Steam flows steadily through an adiabatic turbine, a captivating topic that unveils the intricate interplay of thermodynamics, fluid dynamics, and engineering ingenuity. Adiabatic turbines, the workhorses of various industries, harness the power of steam to generate electricity, propel ships, and drive industrial processes.

This article delves into the fundamental principles, performance characteristics, and diverse applications of adiabatic turbines, providing a comprehensive understanding of their significance in modern engineering.

Steam Properties and Characteristics: Steam Flows Steadily Through An Adiabatic Turbine

Steam is a versatile fluid with unique properties that make it suitable for use in adiabatic turbines. These properties include:

- Pressure: Steam pressure is a key factor in determining the power output of an adiabatic turbine.

- Temperature: Steam temperature affects the efficiency of the turbine, with higher temperatures leading to higher efficiency.

- Enthalpy: Enthalpy represents the thermal energy content of steam and is crucial for understanding the energy conversion process in the turbine.

- Specific volume: Specific volume is the volume occupied by a unit mass of steam and influences the flow characteristics through the turbine.

These properties are closely related to the efficiency of the turbine, with optimal values for each property maximizing energy conversion.

Adiabatic Turbine Operation, Steam flows steadily through an adiabatic turbine

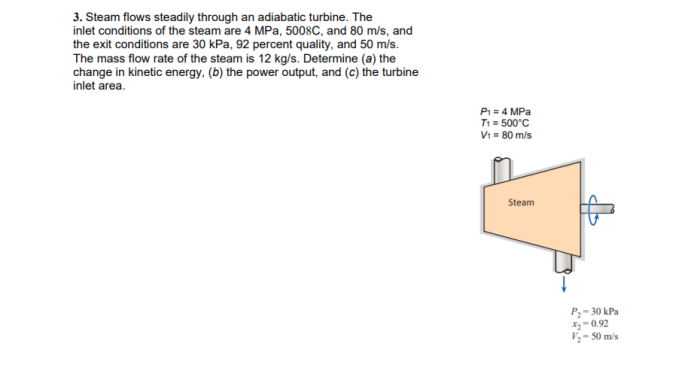

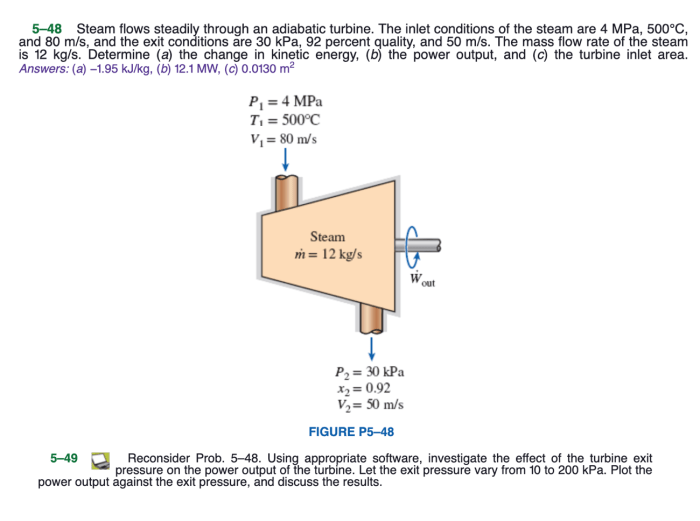

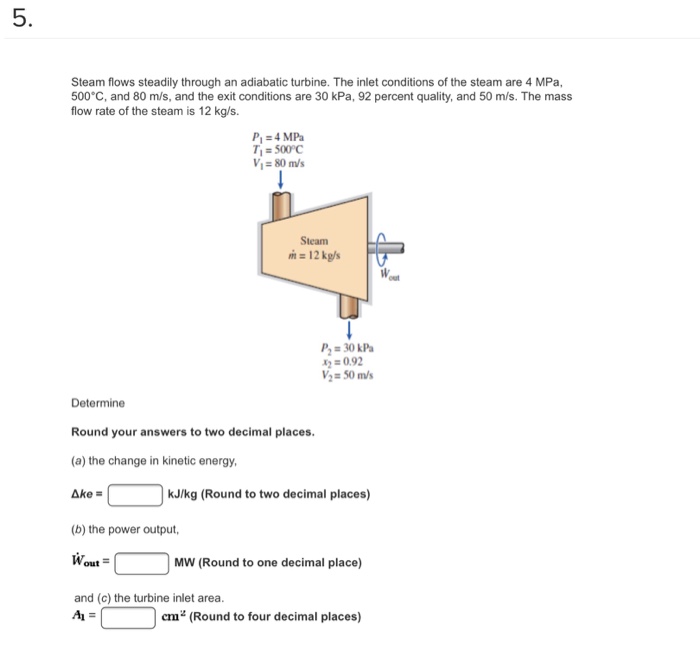

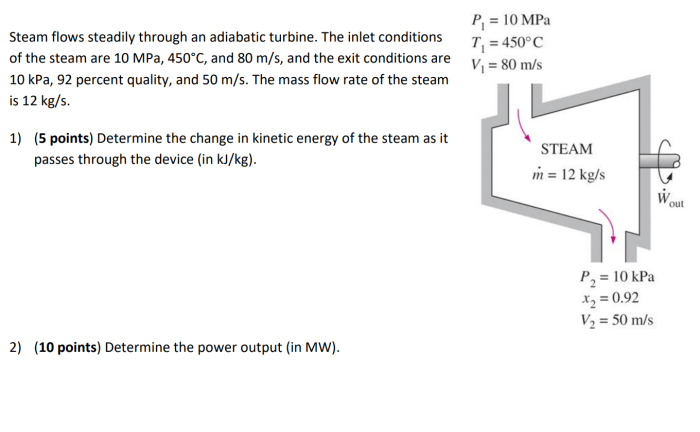

An adiabatic turbine operates on the principle of converting thermal energy into mechanical energy. Steam enters the turbine at high pressure and temperature, and as it flows through the turbine, its pressure and temperature decrease while its velocity increases. The turbine blades are designed to extract energy from the steam by redirecting its flow and converting its kinetic energy into rotational motion.

Flow Dynamics

The flow of steam through an adiabatic turbine is complex and involves several factors:

- Velocity: Steam velocity increases as it flows through the turbine due to the pressure drop.

- Pressure drop: The pressure drop across the turbine is a key factor in determining the power output.

- Reynolds number: Reynolds number characterizes the flow regime and influences the boundary layer development on the turbine blades.

The design of the turbine nozzle is crucial in controlling the flow characteristics and maximizing the efficiency of the turbine.

Efficiency and Performance

The efficiency of an adiabatic turbine is defined as the ratio of the actual power output to the ideal power output. Factors affecting efficiency include:

- Blade design: The shape and design of the turbine blades play a vital role in extracting energy from the steam.

- Steam conditions: The pressure, temperature, and enthalpy of the steam entering the turbine influence the efficiency.

- Operating parameters: Factors such as turbine speed and load affect the efficiency.

Measuring and improving turbine efficiency are essential for optimizing the performance of the system.

Applications and Limitations

Adiabatic turbines have a wide range of applications in various industries:

- Power generation: Adiabatic turbines are used in thermal power plants to convert steam energy into electricity.

- Refrigeration: Adiabatic turbines are used in refrigeration systems to expand refrigerant and produce cooling.

- Process industries: Adiabatic turbines are used in various process industries for power generation and fluid expansion.

Despite their versatility, adiabatic turbines have certain limitations:

- Material limitations: The materials used in the construction of adiabatic turbines must withstand high temperatures and pressures.

- Efficiency limitations: Adiabatic turbines are not 100% efficient due to factors such as friction and heat loss.

Understanding these limitations is crucial for designing and operating adiabatic turbines effectively.

FAQ Summary

What is the principle of operation of an adiabatic turbine?

An adiabatic turbine operates on the principle of converting thermal energy into mechanical energy. As high-pressure steam enters the turbine, it expands through specially designed nozzles, converting its thermal energy into kinetic energy. This high-velocity steam then impinges on the turbine blades, causing them to rotate and generate mechanical power.

What factors affect the efficiency of an adiabatic turbine?

Several factors influence the efficiency of an adiabatic turbine, including blade design, steam conditions, and operating parameters. The shape and angle of the turbine blades play a crucial role in extracting maximum energy from the steam. Additionally, the pressure and temperature of the steam entering the turbine, as well as the rotational speed of the turbine, impact its efficiency.